In a groundbreaking collaboration between NASA and the Department of Energy’s Oak Ridge National Laboratory (ORNL), researchers have achieved a significant milestone in space exploration by successfully 3D printing a prototype lunar rover wheel. This remarkable achievement is set to revolutionize the way we explore the moon and beyond.

The 3D-printed wheel is modeled after the lightweight wheels used by NASA’s Volatiles Investigating Polar Exploration Rover (VIPER), scheduled for a historic moon mission in 2024. While this prototype won’t be used in the actual lunar mission, it serves as a proof of concept, demonstrating the potential of additive manufacturing technology for future space exploration endeavors.

Additive manufacturing, often referred to as 3D printing, offers numerous advantages. It enhances energy efficiency, reduces material waste, shortens lead times, and allows for the creation of complex designs while tailoring material properties. ORNL’s Manufacturing Demonstration Facility (MDF) has been at the forefront of advancing this technology for various industries, including clean energy, transportation, and manufacturing.

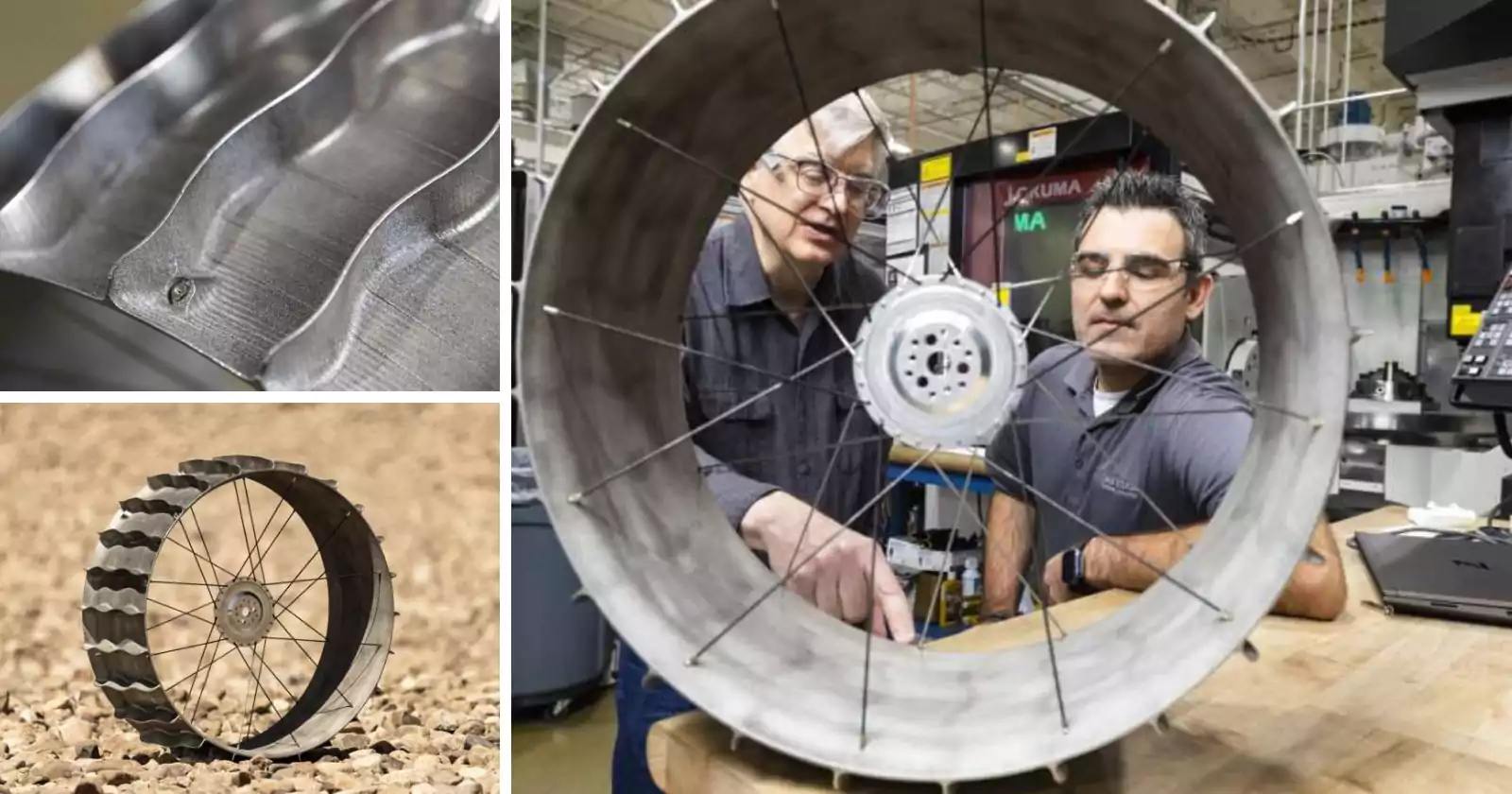

The 3D-printing process for the rover wheel prototype at ORNL is nothing short of remarkable. It employs a specialized 3D printer equipped with two coordinated lasers and a rotating build plate. Unlike conventional metal powder bed systems, this innovative printer operates simultaneously and continuously, significantly increasing production rates and enabling the printing of large objects.

Key to the success of this project was the expertise in process automation and machine control. Researchers utilized software developed at ORNL to slice the wheel design into vertical layers and balance the workload between the lasers, ensuring precise and even printing. This collaborative effort with NASA has propelled the technology forward and marked a significant milestone in space exploration.

The prototype wheel, crafted from a nickel-based alloy, surpasses the size of typical parts printed with metal powder bed systems. Measuring 8 inches in width and 20 inches in diameter, it showcases the advantages of additive manufacturing by allowing for greater complexity in the rim design without increasing manufacturing difficulty or cost.

One of the most exciting possibilities presented by this achievement is the potential for future lunar and Martian missions. The specialized 3D printer used in this project can only build with certain materials, resulting in a 50% heavier wheel compared to the aluminum VIPER wheel of similar thickness. Nevertheless, NASA plans to conduct extensive testing of the 3D-printed wheel’s performance, evaluating maneuverability, resistance to pivoting, sideways slippage, slope climbing, and other critical metrics.

The flexibility of additive manufacturing means that design updates can be rapidly implemented in response to testing, potentially leading to more advanced wheels for future missions. Furthermore, it opens the door to the possibility of off-planet manufacturing capability, which will be essential for crewed research stations on the moon, such as those planned under NASA’s Artemis Program. This capability would enable the production of replacement parts using local materials from celestial bodies like the moon or Mars.

In conclusion, the successful 3D printing of a lunar rover wheel represents a remarkable leap forward in space exploration technology. This achievement not only highlights the innovative capabilities of additive manufacturing but also sets the stage for more advanced and efficient manufacturing processes that will play a crucial role in the future of lunar and Martian missions. NASA and ORNL’s collaboration has truly paved the way for the next era of space exploration.

Leave a Reply